Business

We produce high-quality products using advanced manufacturing technology and rigorous quality control.

Rebar mesh assembly and measurement

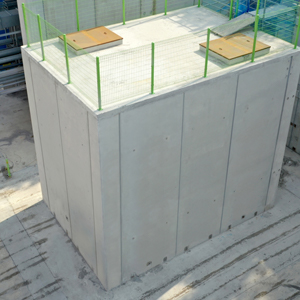

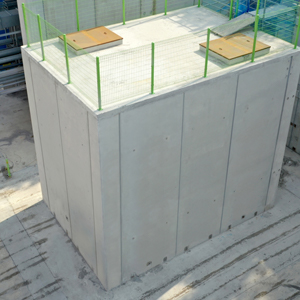

Reinforcement placing and mold assembly

Concrete pouring

Rod compaction and plastering work

Steam curing (using a temperature sensor)

Product demolding after curing

We are doing our best to ensure safety and stability of structures during construction by designing products through accurate structural calculations.

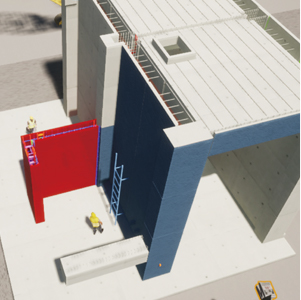

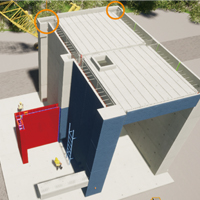

Anchor frame construction

Floor foundation casting

Member import and lifting

Pillar installation

Girder installation

Slab installation

Floor reinforcement placing

Cast-in-place

Installation view

As construction that includes PC production and high construction technological integration, it can be applied to all factory buildings such as main production buildings of semiconductor (UT, CT, FAB buildings, etc.), power plants (154kV), and wastewater treatment plants (WWT).

In addition to manufacturing, it is a building where people involved in knowledge and information and communication industries and business support facilities are located. Recently, most of the knowledge industry centers have applied the PC method to shorten the construction period and maximize the construction effect.

It is a place where goods are stored in the distribution process between production and consumption. In the untact era, the demand for the building increases rapidly, and high-load long span slabs such as DTS/HCS/RPS are mainly used.

It can be constructed separately from the main building, and it is a method being applied to more sites to shorten the construction period and reduce the number of on-site personnel.

As a construction method that converts the roof top structure into PC, it is a construction method that can shorten the construction period by using a tower crane. It is a construction method that improves the appearance of the apartment rooftop and is advantageous in terms of construction period and cost compared to steel frame and RC construction.

The modular construction method can reduce the construction period by 30% or more on average compared to the existing method (RC)

When constructing a building that requires a high load, it can reduce costs by reducing the cross-sectional area of members by introducing pre-tension and reducing the amount of materials such as temporary materials and molds

High quality can be secured by pre-fabrication of members in a factory with optimal production conditions

Maximization of mechanized work during construction reduces the number of on-site workers and secures safety

Optimized for urban construction with dense population and buildings due to low noise and dust generation

It is an innovative double wall that enhances durability and reduces the cross-section thickness by 100mm compared to the existing double wall by using a mixture of shear reinforcing bars and reinforcing materials that connect the panels (walls). As the thickness is reduced, cost reduction and productivity can be expected.

IS DONGSEO DOUBLE WALL(7M) IS DONGSEO DOUBLE WALL(15M)

These are two types of hollow columns in which hollow parts are made of duct / steel plate. Unlike the existing hollow column, it is an efficient column that can secure more than 50% of hollowness by replacing the main middle bar with a square pipe.

It is an exterior wall construction method that for an integrated wall by embracing columns rather than ‘pillar-external wall-pillar’. If the basement external wall that resists earth pressure is applied as a PC member, it can be constructed quickly and accurately and shorten the construction period by increasing productivity.

Patent No. 10-2020-0108104

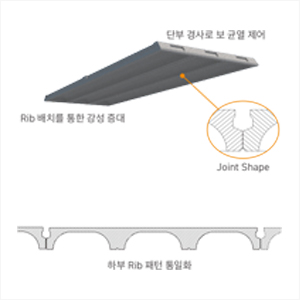

It is a slab that forms a slab without inserting a separate material in a hollow part, secures a Topping Con’c filling space, and implements an unshored Deck system by increasing rigidity.

Patent No. 10-0009911

This slab is implemented to minimize the amount by forming a hollow part divided by the lower ribs, and to distribute the concentrated load on the ribs by forming inclined surfaces at both ends and to prevent concrete leakage when pouring the Topping Con’c.

Patent No. 10-1588161

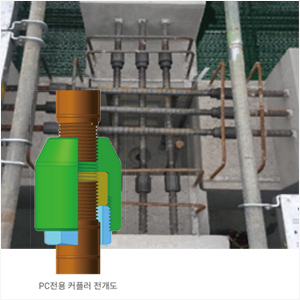

As a coupler that can overcome production/assembly errors that may occur in the connection of PC members, rather than rebar joint of the general RC method, it is suitable for one-to-one joint seismic structure.